CNC Mold Maker: Elevating Precision in Metal Fabrication

The realm of metal fabrication has witnessed a revolutionary transformation with the advent of Computer Numerical Control (CNC) technology. Among the most significant innovations in this field is the role of the cnc mold maker. As industries evolve and the demand for high-quality components increases, the expertise of a CNC mold maker becomes paramount. At deepmould.net, we specialize in crafting precision molds that not only meet but exceed industry standards.

Understanding the Role of a CNC Mold Maker

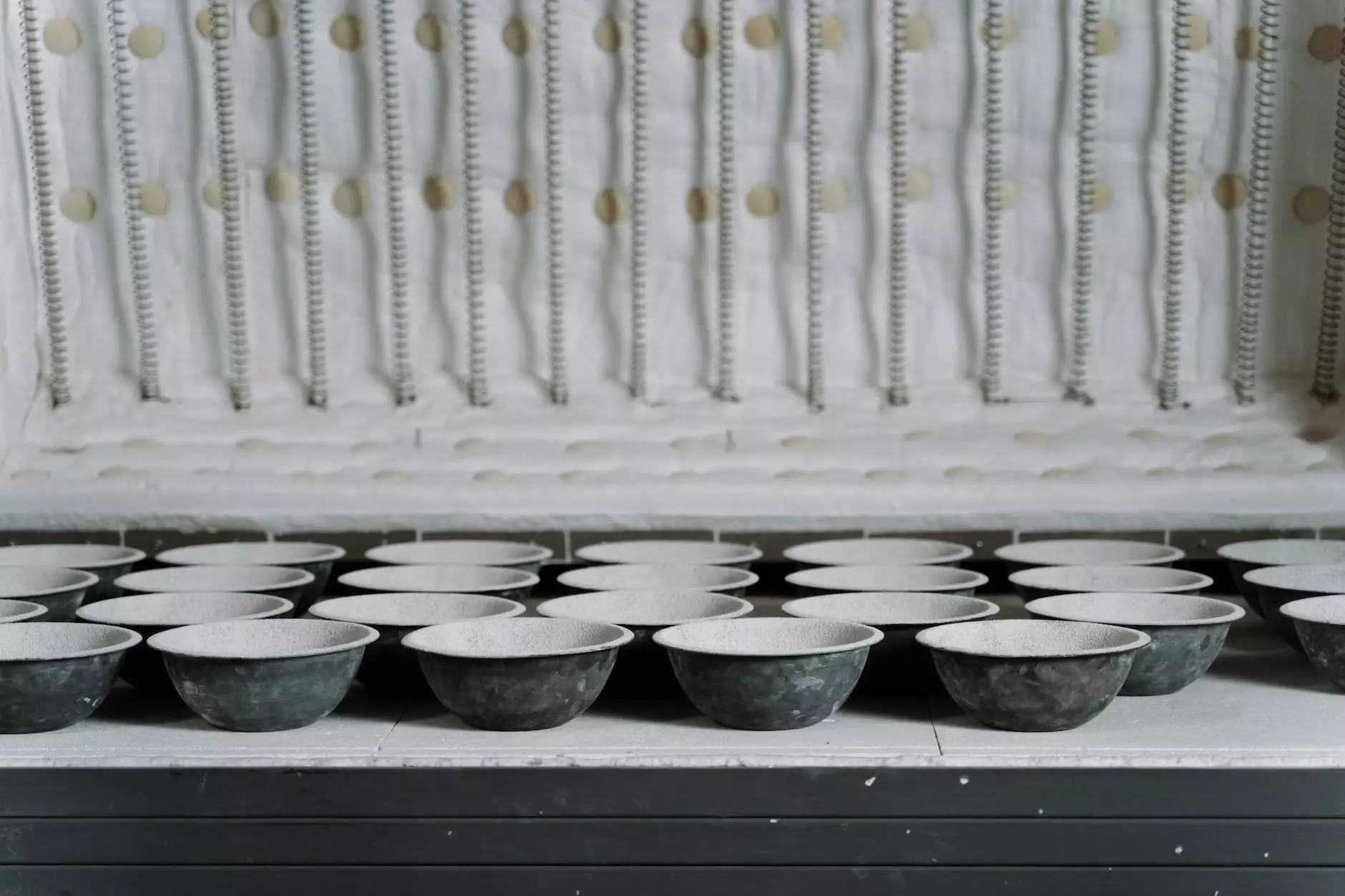

A CNC mold maker is not just an artisan; they are a vital component of the manufacturing ecosystem. Their primary responsibility involves designing and creating molds that are used in the production of various metal parts. These molds are essential in producing consistent, precise components necessary for a wide array of industries, including automotive, aerospace, medical, and consumer goods.

Key Responsibilities of a CNC Mold Maker

- Designing Molds: Utilizing CAD software to design intricate mold layouts that meet specific client requirements.

- Programming CNC Machines: Translating designs into machine code, ensuring that CNC equipment operates flawlessly.

- Machining Components: Operating CNC machining equipment to create precise mold parts, often from durable materials like steel and aluminum.

- Quality Assurance: Conducting rigorous testing and quality checks to ensure the molds produced meet exact specifications.

- Maintenance and Troubleshooting: Performing routine maintenance on machinery and troubleshooting any issues that may arise during production.

The Importance of Precision in CNC Mold Making

Precision is the cornerstone of manufacturing, particularly in sectors where even the slightest deviation can lead to product failure or safety violations. The cnc mold maker employs advanced techniques and technologies to ensure that every mold produced is accurate to the specifications provided. This includes:

Advanced Technology Utilized by CNC Mold Makers

CNC mold makers leverage various technologies to enhance precision and efficiency in their workflow:

- Computer-Aided Design (CAD): Software that allows mold makers to create detailed 3D models of the required molds, facilitating precise design.

- Computer-Aided Manufacturing (CAM): Software that assists in programming CNC machines, ensuring accurate execution of the design.

- 3D Printing: Rapid prototyping techniques that allow for the quick production of mold prototypes, providing a tangible reference for testing.

- Laser Cutting: A method for achieving extremely precise cuts, essential for creating detailed mold features.

Benefits of Choosing a Skilled CNC Mold Maker

Selecting an expert cnc mold maker offers numerous advantages that ultimately impact the quality and cost-effectiveness of production:

- Enhanced Quality: Precision molds result in superior components, reducing the risk of defects in the final products.

- Efficiency Improvements: CNC mold makers optimize the manufacturing process, saving time and resources.

- Custom Solutions: Experienced mold makers can tailor designs to meet unique requirements, offering bespoke solutions for specialized applications.

- Lower Production Costs: High-quality molds produce components that require less rework, minimizing costs associated with defects and failures.

- Support and Maintenance: Competent CNC mold makers provide ongoing support and maintenance, ensuring longevity and reliability of molds produced.

Applications of CNC Mold Making Across Industries

The versatility of CNC mold making allows it to be utilized in various industries, showcasing its importance in modern manufacturing:

1. Automotive Industry

The automotive sector relies heavily on CNC mold makers to produce components such as dashboards, bumpers, and various chassis parts. Precision in these molds ensures that parts fit together seamlessly, promoting safety and functionality.

2. Aerospace Industry

Aerospace applications demand the highest levels of precision, and CNC molds are crucial for producing components such as wing structures and engine parts. The ability to craft lightweight yet robust molds is essential in this field.

3. Medical Devices

Quality and precision are non-negotiable in the medical industry. CNC mold makers provide molds for devices like surgical instruments and diagnostic equipment, ensuring they meet stringent regulatory standards.

4. Consumer Goods

The production of household items, toys, and electronic devices often requires custom molds designed by CNC mold makers to meet consumer preferences and safety regulations.

Finding the Right CNC Mold Maker for Your Business

When it comes to selecting a cnc mold maker, several factors should influence your decision:

Experience and Expertise

Look for mold makers with a proven track record in your specific industry. Experience directly correlates with the quality and reliability of the molds produced.

Technology and Equipment

A modern CNC mold maker should invest in state-of-the-art technology and equipment. This ensures they can handle complex designs and produce high-quality molds efficiently.

Customization Capabilities

Your business needs molds tailored to your specific requirements. A good CNC mold maker should be flexible and innovative in providing custom solutions.

Quality Assurance Processes

Inquire about the quality assurance processes in place. Rigorous testing and verification procedures are crucial for ensuring that the molds produced meet stringent standards.

Conclusion: The Future of CNC Mold Making

As industries continue to demand more from their manufacturing processes, the role of the cnc mold maker will only grow in significance. With advancements in technology and increasing complexities in design, the expertise of CNC mold makers will be indispensable for businesses striving to maintain a competitive edge. At deepmould.net, we are committed to providing unparalleled CNC mold making services that drive innovation and success for our clients.

Contact Us for Your CNC Mold Making Needs

If you are in search of a reliable and skilled cnc mold maker to elevate your manufacturing processes, look no further. Reach out to us at deepmould.net today, and let us assist you in achieving the precision and quality your business requires.